Capability

Our engineering & manufacturing capability, across a broad range of engineering disciplines, continues to evolve through investment in people, technology & certification so that we can deliver for our clients today and into the future.

· Our management systems are ISO 9001:2015 certified to ensure consistent quality

· We are certified for both AS/NZS 2980:2007 welding for fabrication of dairy standard equipment and also ASME IX:2007 for welding of pressure rated equipment

· In 2016 we will be dual certified for compliance with both ASME U1 as well as the European Pressure Directive (PED)

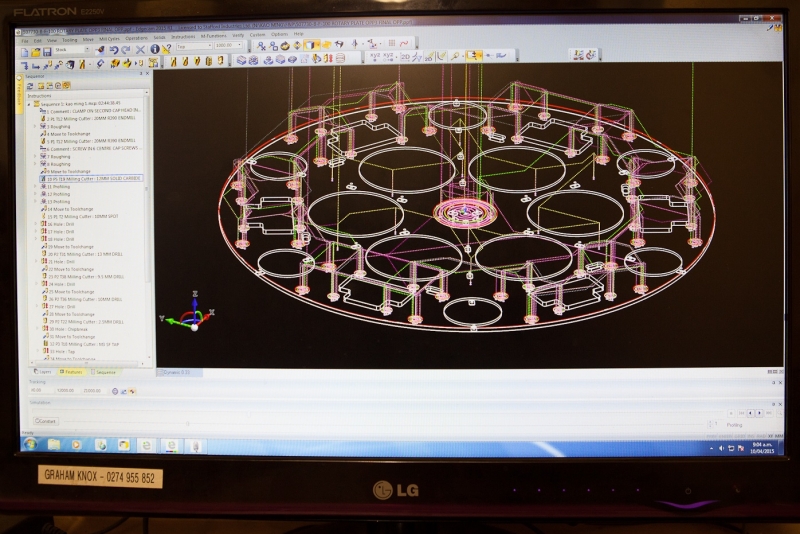

Engineering Software

3D Design Software

We have four highly trained technicians operating Autocad and Solidworks and multiple workstations to write machine code using Edgecam.

Precision Engineering

Manual Turning

2 x manual centre Lathes

CNC Turning

1 x Teach Lathe by Takasawa.

3 x Alpha 550 CNC Teach lathes by Harrison.

1 x V turn II 26Y CNC lathe with live tooling by Victor.

Manual Milling

4 x 4VS turret mills by Maximart

CNC Milling

1 x KMC 2000SD and 1 x KMC 4000 SV double column bridge type machining centres by Kao Ming.

1 x 4VA and 1 x 5VA C frame type machining centres by Okuma.

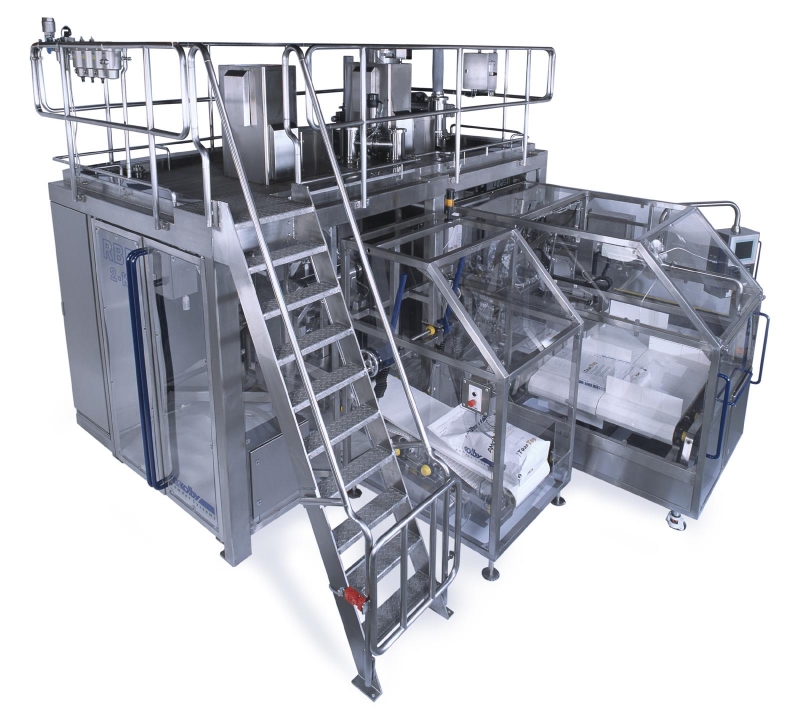

Fabrication

Cutting & Forming

1 x Amada AF 2000E (2kW) laser

1 x Amada FBD III-NT 1025 brake press

1 x Amada HA 250 band saw

1 x Durma MRBS motorised plate rolls 1500 x 6mm

1 x MEP Shark 282 SX band saw

1 x Pearson guillotine 2500 x 6mm

1 x 150t hydraulic press

Welders

10 x Lincoln Electric Invertec V270 T Pulse TIG work stations.

1 x Lincoln Electric Power Wave 455 amp M/STT Pulse MIG.

1 x Miller Dialarc HF-P CY50 300 amp AC/DC TIG for ali.

Miscellaneous

4 x SS polishing stations and acid bay.

Workshop Capacity

Workshop Site Plan

View here

Cranage

Capacity: 1 x 5t/5t, 1 x 3.2t, 6.0m under hook by Abus Crane Systems

Site Services

Site Services

Experienced crews for installation & site servicing.